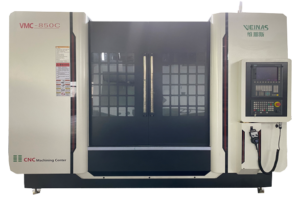

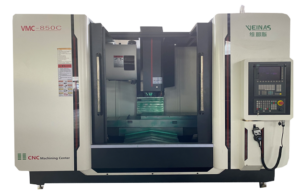

VMC-850C

Vertical machining center is a kind of small and medium-sized machining center. It is designed by mechatronics and has high stability and reliability. It has a beautiful appearance and can be used for precision cutting. After the workpiece is clamped once, the machine tool can automatically and continuously complete the processing of milling, drilling, boring, expanding, reaming, tapping and other processes. It is suitable for the multi variety processing of medium and small boxes, plates, disks, shells and other complex parts. It is widely used in automobile parts, valves, engineering machinery, it equipment, optical equipment, medical equipment, aerospace and other industries.The brand of vertical spindle unit is KENTURN, the brand of screw bearing is NSK / NTN in Japan, the brand of ball screw and linear guide is HIWIN in Taiwan, the brand of main electrical appliances is Schneider, the brand of pneumatic components is SMC, and the CNC system is Mitsubishi, Siemens and Fanuc.

SPECIFICATION

Specification | Unit | Model Nr. |

Three axis stroke (x / Y / Z axis) | mm | 800/500/500 |

Distance from main shaft to column | mm | 570 |

Distance from spindle nose to workbench | mm | 150-650 |

Table size (length × Width) | mm | 1000-500 |

Number of T-shaped slots × Groove width × spacing | 5*18*90 | |

Spindle speed | rpm | 10000 |

Spindle taper hole | BT40 | |

Spindle motor power | kw | 7.5/11 |

Fast moving speed (x / Y / Z axis) | m/min | 48/48/48 |

Cutting feed movement | Mm/min | 1-20000 |

Number of tools | handful | 24 |

Maximum tool diameter / length / weight | Φ78mm/300mm/8kg | |

Maximum tool diameter (full tool / empty adjacent tool) | mm | Φ130 |

Tool selection mode | Arbitrary / sequential selection | |

Tool exchange time (tool to tool) | s | 1.8 |

Maximum drilling diameter | mm | Φ40 |

Maximum tapping diameter | mm | M20 |

Milling capacity | cm³/min | 200 |

Machining accuracy | mm | 0.006/300 |

repeat positioning accuracy | mm | 0.006/300 |

Table bearing | kg | 600 |

Net weight (about) | T | 4.2 |

Overall dimension (L × wide × High) | mm | 3000/2800/2500 |